Polyethylene (PE) pipelines are being used more and more across the globe in drinking water distribution networks due to the intrinsic qualities of the material, namely durability, ductility, ease of laying and connecting, and the total absence of corrosion, even in harsh environments.

PE is recognised for its technical and sanitary qualities and had proved itself in terms of drinking water network management. Its reliability was unquestioned until about 10 years ago, when stress cracks started to appear in certain pipelines. Tests were carried out which revealed that the PE pipes were being oxidised by disinfectants such as chlorine and chlorine dioxide, leading to the supposition that it was a generalised phenomenon. It was not. In actual fact, the phenomenon can only occur under certain precise circumstances and is the result of three factors acting in conjunction: a high concentration of disinfectant, a high water temperature and non-compliant laying conditions.

Certain types of raw water require treatments that can appreciably increase the concentration of chlorine in the network. When combined with a high temperature, these concentrations can provoke thermo-oxidation of the polyethylene which will be considerably more vulnerable if the laying conditions are non-compliant.

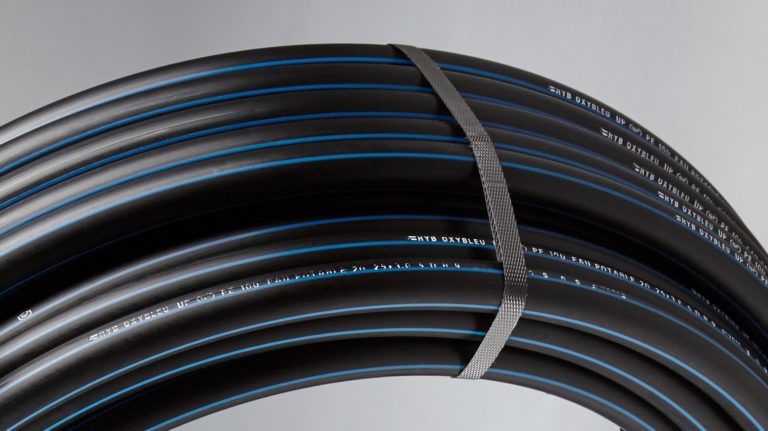

To counter this problem, the manufacturers have developed new pipes with improved disinfectant resistance characteristics. Certain types of pipe also have improved slow crack growth resistance such as the OXYBLEU PE100 RC range.

With the advent of the NF114 Mark regulations, these pipes can be used for harsh applications such as high water temperatures and disinfectant concentrations and uncertain laying environments, and provide durability and long service.

MAB