When carrying pressurised raw water or evacuating non-potable or industrial water, the pipework must have an optimum level of water-tightness whilst being mechanically strong and resistant to chemicals and heat.

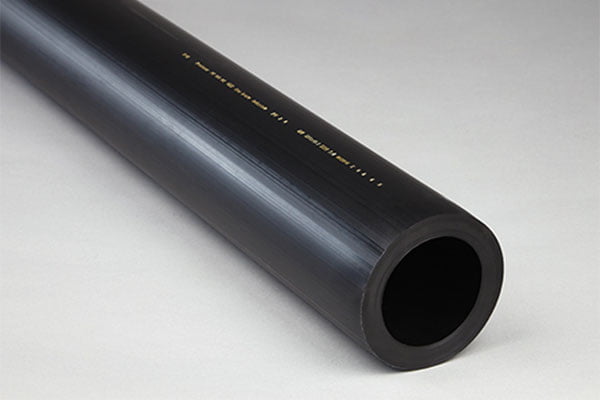

Because of polyethylene’s flexibility, impermeability and resistance to impacts and crushing, it remains the material of choice for this type of application. PE is impervious to the majority of chemicals, pollutants and so on.

Application examples

Conventional installation

Laid in the traditional way in trenches, PE pipework can accommodate ground movements without any effect on its mechanical properties. Any stresses caused by such movements disappear over time thanks to the visco-elastic properties of polyethylene and the relaxation phenomenon.

Water pipes

Our polyethylene water pipes are designed for pumping seawater for use in desalination plants, amongst other things. Because it is completely unaffected by seawater, it is extremely durable.

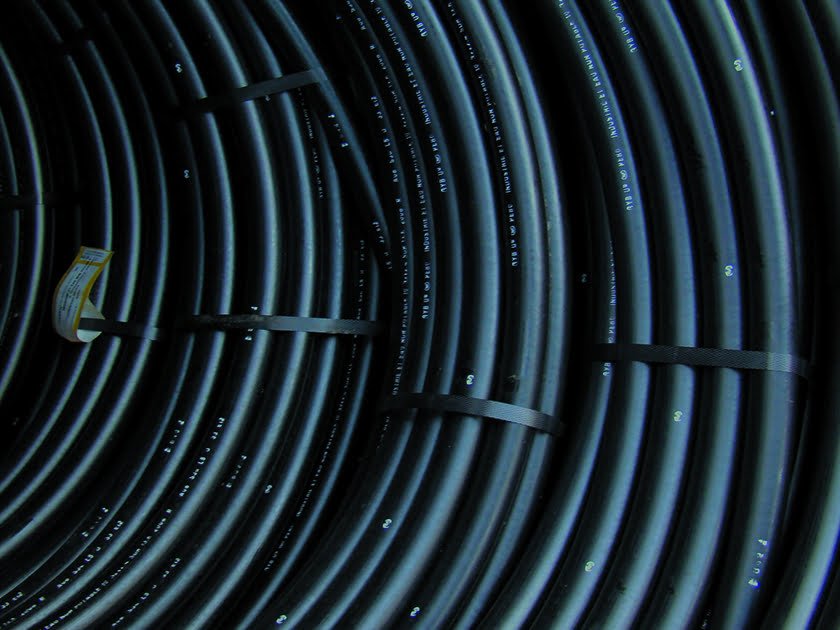

Snow cannons

Our polyethylene piping can be used to supply compressed air to snow cannons sited at the top of ski slopes. PE100 pipes are able to withstand very high pressures and flow rates, and this confers great strength on the piping, giving it an exceptionally long service life.

Compressed air

Polyethylene remains the material of choice for transporting compressed air.

Sea outfalls

PE100 High Density Polyethylene remains the ideal material for sea outfalls as it can transport any type of fluid under the sea. Sea outfalls contribute to the quality of littoral waters.

Marine farms – Oyster farming

Thanks to its flexibility and buoyancy, PE piping is ideally suited to the construction of marine farms in general and oyster farms in particular.